Novares is a French company of plastic experts based in Velizy Villacoublay, near Paris. They design complex components and systems for virtually every automaker in the world, and many tier-1s, and manufacture them with innovative, cutting-edge techniques for greener, lighter-weight cars in pursuit of the CASE megatrends—Connected, Autonomous, Shared, and Electric.

Novares is inside 1 car out of 3 worldwide. The company has a footprint covering 22 countries, with 37 manufacturing plants, 6 skill centers, 7 technical centers, and 17 customer service centers. They achieved a turnover of €1.2bn in 2023.

DVN Interior met with Novares’ management and innovation teams to learn more about this remarkable company. We met Group Innovation Director Hugo Mestre, and the Interior Skill Center Director Richard Piercy.

DVN Interior: How did Novares come to exist?

Novares: Novares was created in 1955 as Mecaplast in Monaco and the group first production of chemical condenser caps started. Mecaplast became known for making a durable plastic fan used in the popular Peugeot 204’s engine, and later the first-ever thermoplastic cam cover, and in 2004, non-woven synthetic media for air filtration and also in oil separation devices for cam covers. Since 2012, under CEO Pierre Boulet, Mecaplast has continued to grow as a key supplier to automakers, offering a large product range in engine, interior and exterior trim.

In 2017 Mecaplast became Novares, following the acquisition of Michigan-based Key Plastics.

DVN-I: Why Monaco? That’s a pretty unusual place in the automotive world.

Novares: Founded by Charles Manni, a big contributor to the Monegasque economy, the company started with five employees in a small 15-meter warehouse. They focused on producing a variety of automobile parts for local distributors and auto manufacturers. We maintain a presence there since!

DVN-I: You’ve come a long way since that small warehouse!

Novares: 2023’s global revenue was €1.2bn, with a workforce of 9,000 persons, including 550 engineers.

DVN-I: How is Novares organized?

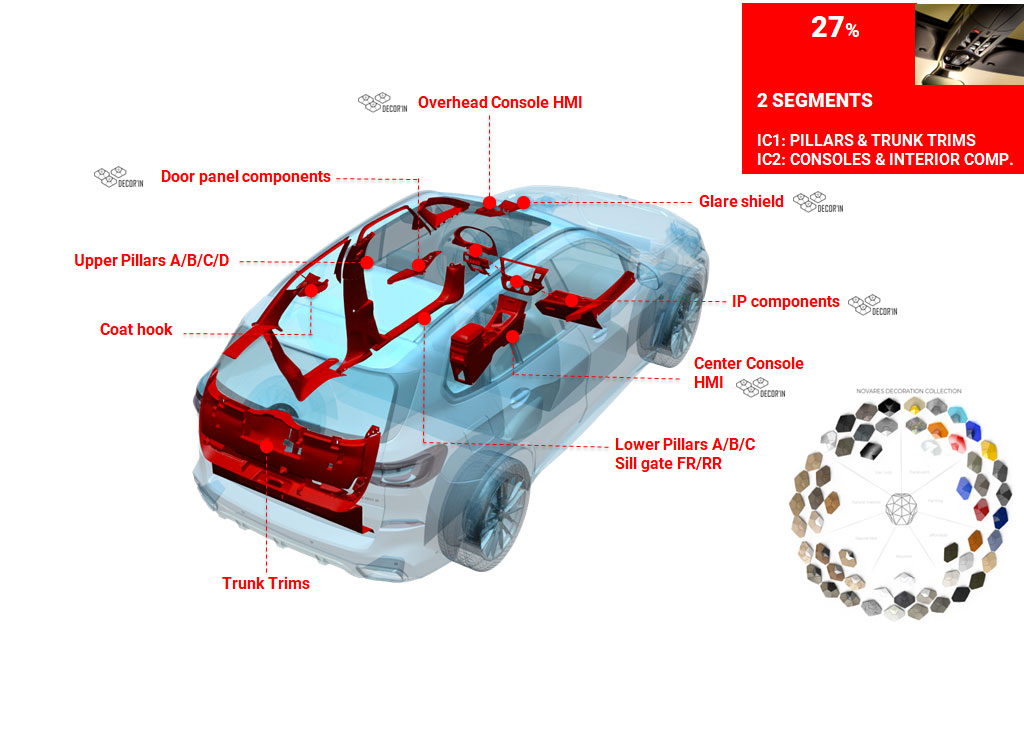

Novares: We are organized around five product lines, with their respective share of our total business:

- Powertrain (36 per cent)

- Interior Components (27 per cent)

- Exterior (24 per cent, paints and surfaces)

- Opening Systems (8 per cent)

- Air Vents (5 per cent)

These product lines enable Novares to provide global plastic-based solutions to the automotive industry, for engine, interior, and exterior applications.

DVN-I: What is the difference between your skill centers and technical centers?

Novares: A skill center is in charge of innovation for the product line and supports all business units selling it to the customers and bringing deep engineering expertise. We have one skill center per product line, Monaco is where the interior components skill center is.

The technical centers oversee program development (R&D), program management, and engineering costs, and they serve multiple product lines. They are in Czechia, India, Mexico, Morocco, Romania, and Turkey. Our proximity with production plants is very important for smooth product and process development. It also helps relationships with OEMs and tier-1s locally.

DVN-I: How is your revenue divided among customers and regions?

Novares: Western Europe leads with 31 per cent, followed by USA (18 per cent), Eastern Europe (17 per cent); Mexico (16 per cent), China (12 per cent), and then Turkey, North Africa, India, and Brazil. From a customer portfolio standpoint, the group produces for Stellantis, Ford, Renault/Dacia, BMW, GM, Nissan, Toyota, Audi, and others, including newcomers like Tesla. Customers also include tier-1s such as Yanfeng, Forvia, Bosch, and many others. The backlog included is worth five years in sales.

DVN-I: What does your motto ‘Beyond Plastics’ signify?

Novares: It means we are a complete solutions provider serving our customers’ needs. We use advanced plastics injection technologies, and we design highly engineered solutions, beyond commodity plastics, to be user-friendly, ergonomic and affordable.

We create and produce components and systems with multi-functionalities that add value. Our parts have complex functions, mechanisms, use kinematics, mechatronics and provide integration expertise for modules.

Our plastics match metal performance, plus offer the lightweight dynamic contributing to the production of lightweight cars, especially EVs, where any saved gram can be transformed into km of range.

Our capabilities are to produce quality products and systems reinforced by continuous improvements (trails and errors) and this goes beyond just manufacturing, it guarantees customers all the latest techniques, with service.

Our plastic heat exchanger is a good example. It allows the replacement of conventional aluminum alloy heat exchanger with a plastic part, which can be integrated more easily into engine parts such as an air intake manifold.

DVN-I: And how do interior components factor in with ‘Beyond Platics’?

Novares: For Interior components parts, our product innovation strategy relies on three pillars:

- Plastic ‘instrumentalization’, where beyond means plastronics, integration of electronics, sensors, interior lighting, and so on.

- Plastic CO2 reduction; here beyond means reduction of CO2 footprint, bio-sourced materials, and circular economy.

- In electrification, beyond applies obviously to powertrain, and has consequences as well in term of interior design, including CMF (color, material, & finish).

DVN-I: Design and attractiveness are central to interiors. How do you address these?

Novares: That’s very true, and that’s why decoration is a key dimension for us, with eye-catching decoration solutions, easily packageable into a car interior. It includes parts and surfaces with natural aspect and feeling, textile, translucency/diamond-like effects, and ambient lighting.

DVN-I: What are some of your innovations you’re most proud of?

Novares: From disruptive perspective, we can mention Active Plastic: no more switches, as plastic becomes the sensor! Also, our Touch & Feel customizable HD haptic system.

Looking at incremental innovations, Nova W8 (weight saving technology) and Ultra Mat (cost effective light absorption surface) both bring major VAVE features to the automotive market, including a big step for decarbonization.

DVN-I: Plastic becomes a sensor—fascinating! Can you tell us more?

Novares: It came froma partnership we started four years ago with TG0, a UK-based startup. The idea was to integrate TG0 technology into Novares products.

It is based on efficient low-cost capacitive touch sensors and controllers on the product surface to enable touch-sensitive, pressure-mapping surfaces that enable to reimagine products and interfaces through touch, twist, swipe, turn, and so on without adding any layer of electronics behind, meaning a sustainable construction. Targeted products include center consoles, overhead consoles, seat controllers, instrument panels, door handle controllers…the list goes on!

Novares brings our expertise in the production of advanced solutions with intelligent and intuitive interfaces integrating TG0’s innovative solutions sought by new-gen EVs. Using the same sustainable approach, both companies’ value is based on building more with less, which means fewer materials, lower energy consumption, and easy recycling for a more powerful product that leads up to 33-per-cent CO2 reduction.

DVN-I: How did you find TG0?

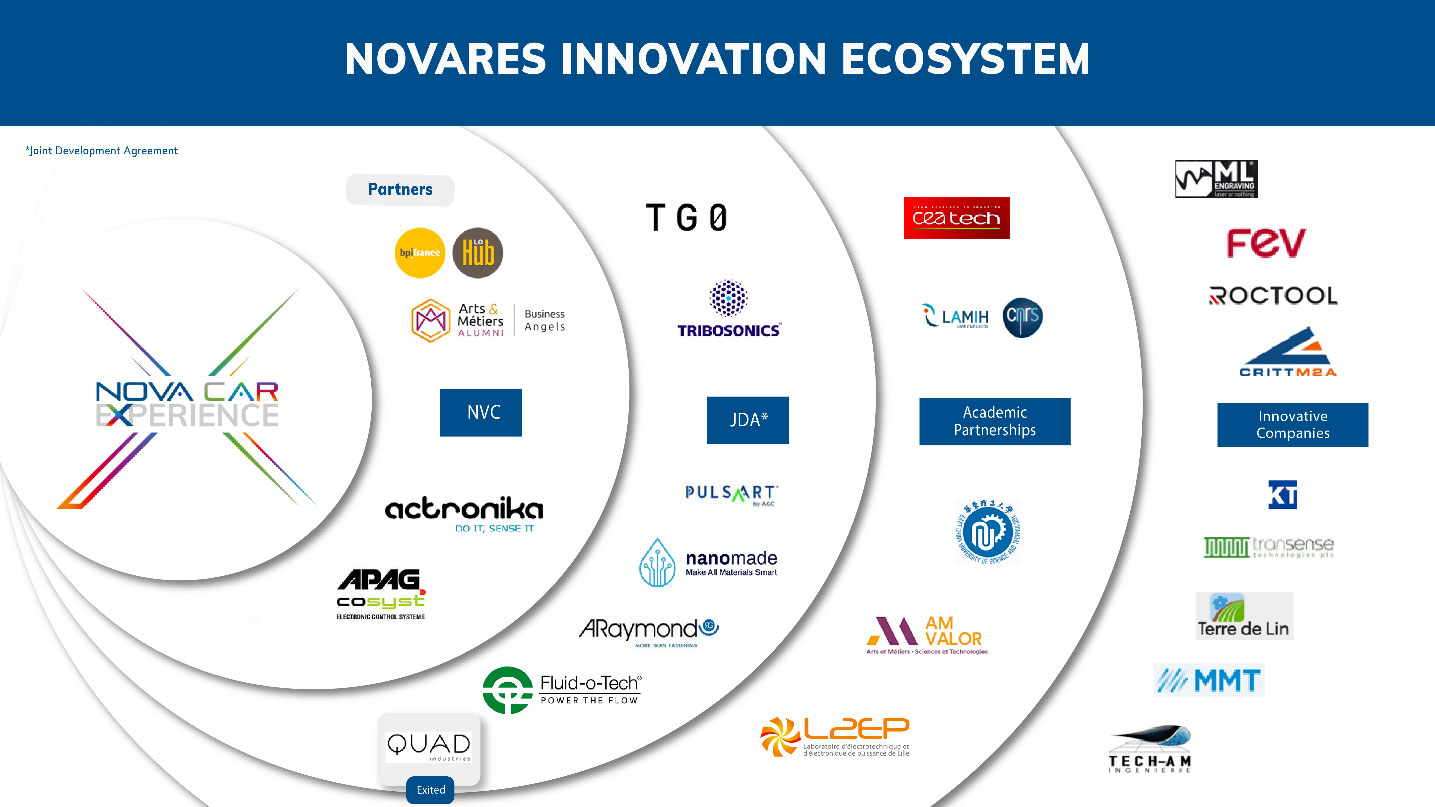

Novares: We started co-working with a few partners in 2018 through Novares Venture Capital, then quickly enlarged our collaboration to startups and innovative compagnies. TG0 is one of the successful partnerships resulting from a strong team spirit between the two companies, reinforcing the commitment to rely on each other’s complementary skills.

DVN-I: What does Novares Venture Capital do, overall?

Novares: The idea is to add ‘technology bricks’ beyond our plastics, and to help those startups to transfer their technology and expertise into the automotive world, which is very demanding in term of specification, quality and mass production. The target is not to acquire these companies, which are often successful in other industries.

DVN-I: You mentioned Novacar; what is that?

Novares: Novacar is not a concept vehicle as such, it is more an innovation carrier, where we showcased, in real car environment, many different innovations. We will be building soon a fourth generation of an approach we started in 2018; it is called Novacar eXperience, to emphasize the user experience dimension we want to convince our customers about. Each car has a lifetime of 18-24 months, where we tour the vehicle around customers and continents. It integrates around 20-25 innovations per vehicle. It has no public exhibition, only customer visits.

DVN-I: Can you tell us more about the Monaco Interior Skill Center?

Novares: In this historical location for Novares, we manage all interior innovation projects, with all project teams, product, process, and technology experts, all the development tools (e.g., CAE), and the different labs for metrology and validation.

We master all product and process technologies for interior trim, such as injection, foaming in-mold technologies, decoration, assemblies, and wrapping, to name a few. HMI and kinematics are also important expertises worth mentioning.

DVN-I: Can you mention some interior innovations you have developed?

Novares: Our Ultra Mat technology is a good example. It is an anti-glare solution for video camera systems. There are more and more cameras in or out of the vehicle, and they can all be disturbed by light. The idea here is to have external light absorption in the camera housing, through fine engineered texturing, without any paint or any post injection operation. It saves costs, and limits carbon footprint.

DVN Interior: What’s hot in bio-sourced materials at Novares?

Novares: A good example is Natur’In, a natural-fiber decoration insert backmolded with bioplastics. It can be used anywhere in interior trim—IP, Door, Console, Seat Back cover, etc.

The A-surface is made of thermoformed natural flax fibers, and the part itself is made of injected bioplastics, keeping all the possibilities of injection, such as ribs, locators, clips, and such for integration.

Flax fibers come from Terre de Lin, a French agricultural cooperative, in a supply chain compliant with automotive requirements.

This solution fits with automotive design and CMF trends, visible and touchable sustainability, while being really sustainable, and part of a virtuous circular economy.